AutoKut 100 Slitter & Cut to Length Line Features:

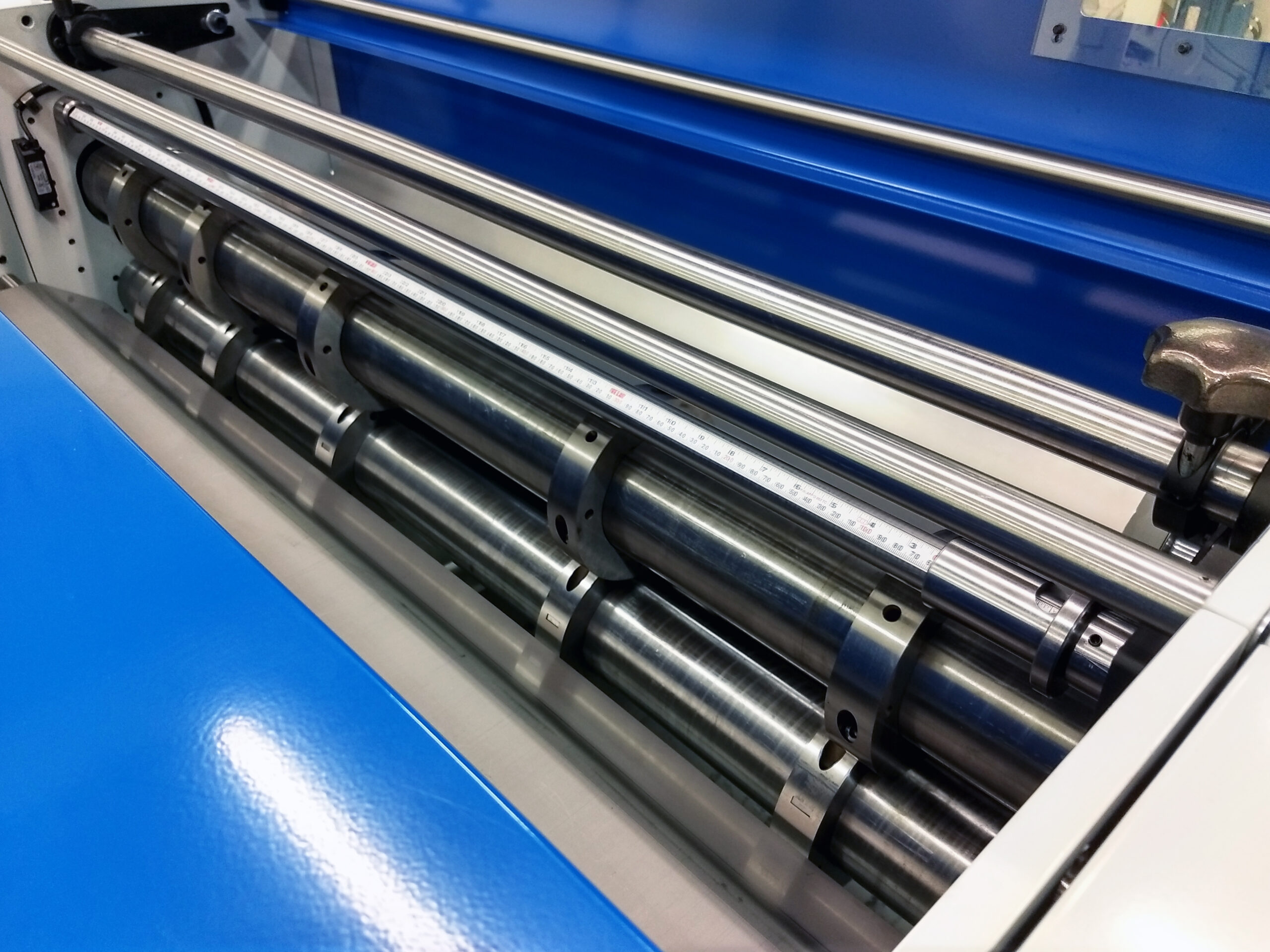

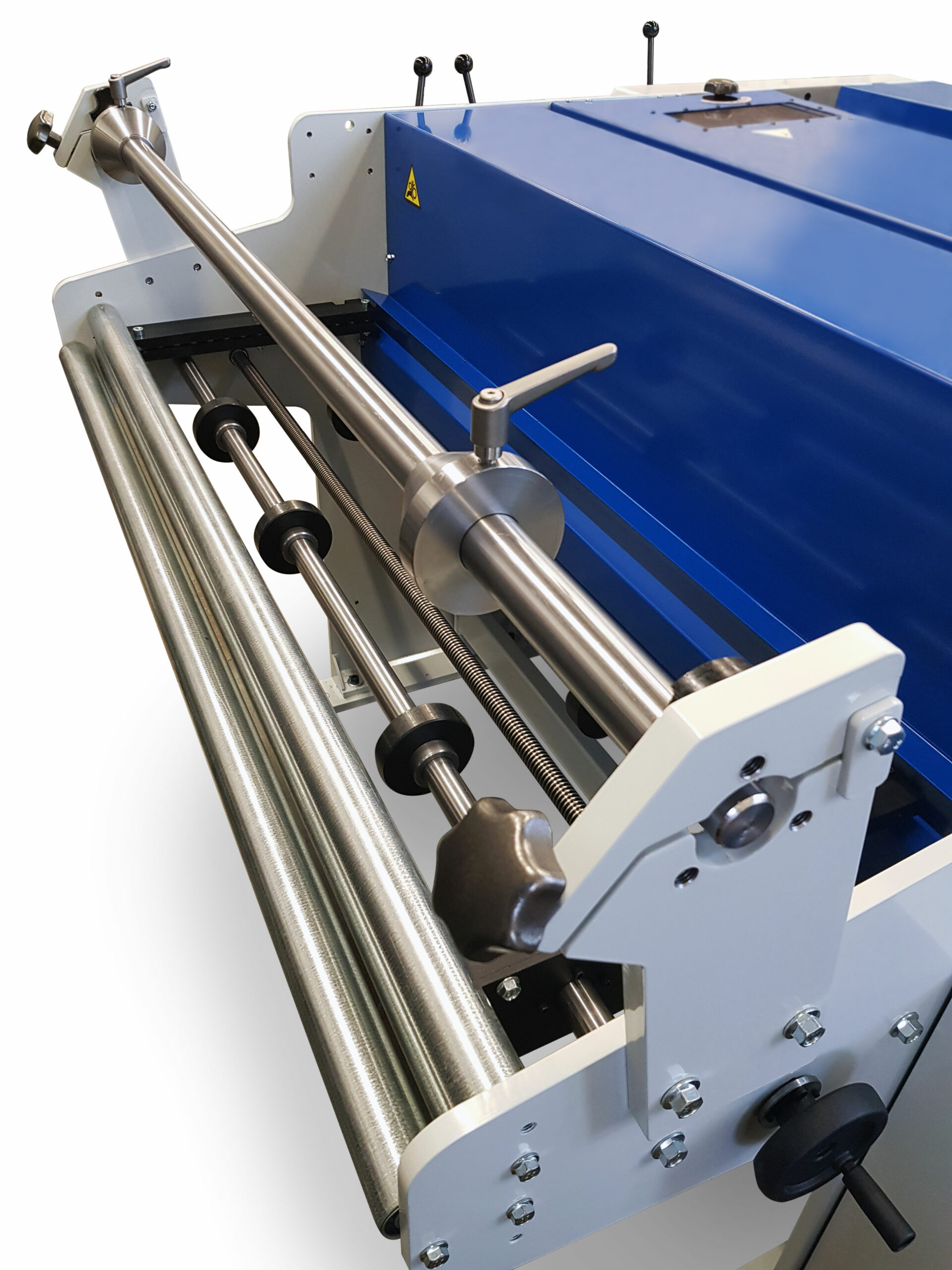

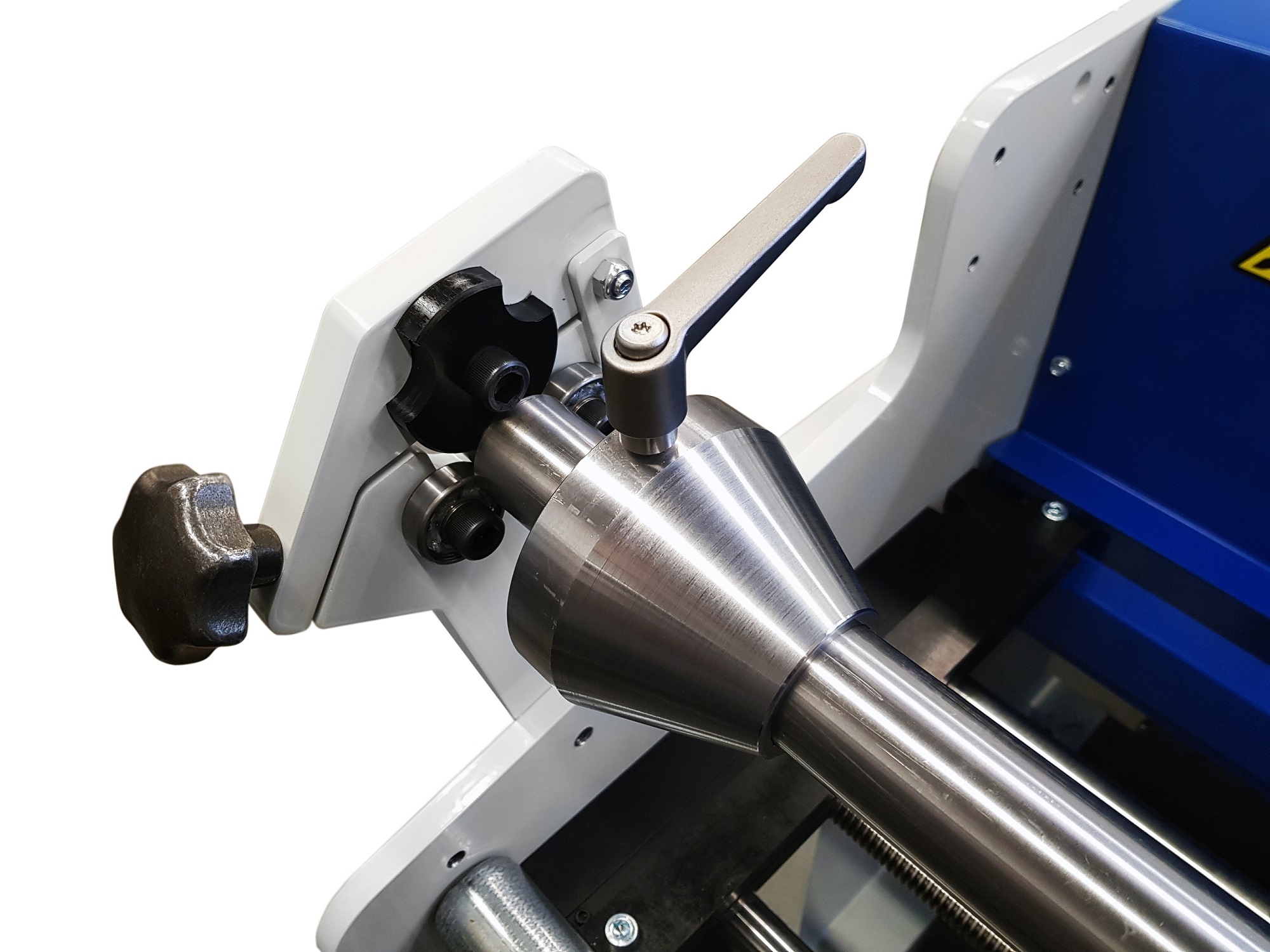

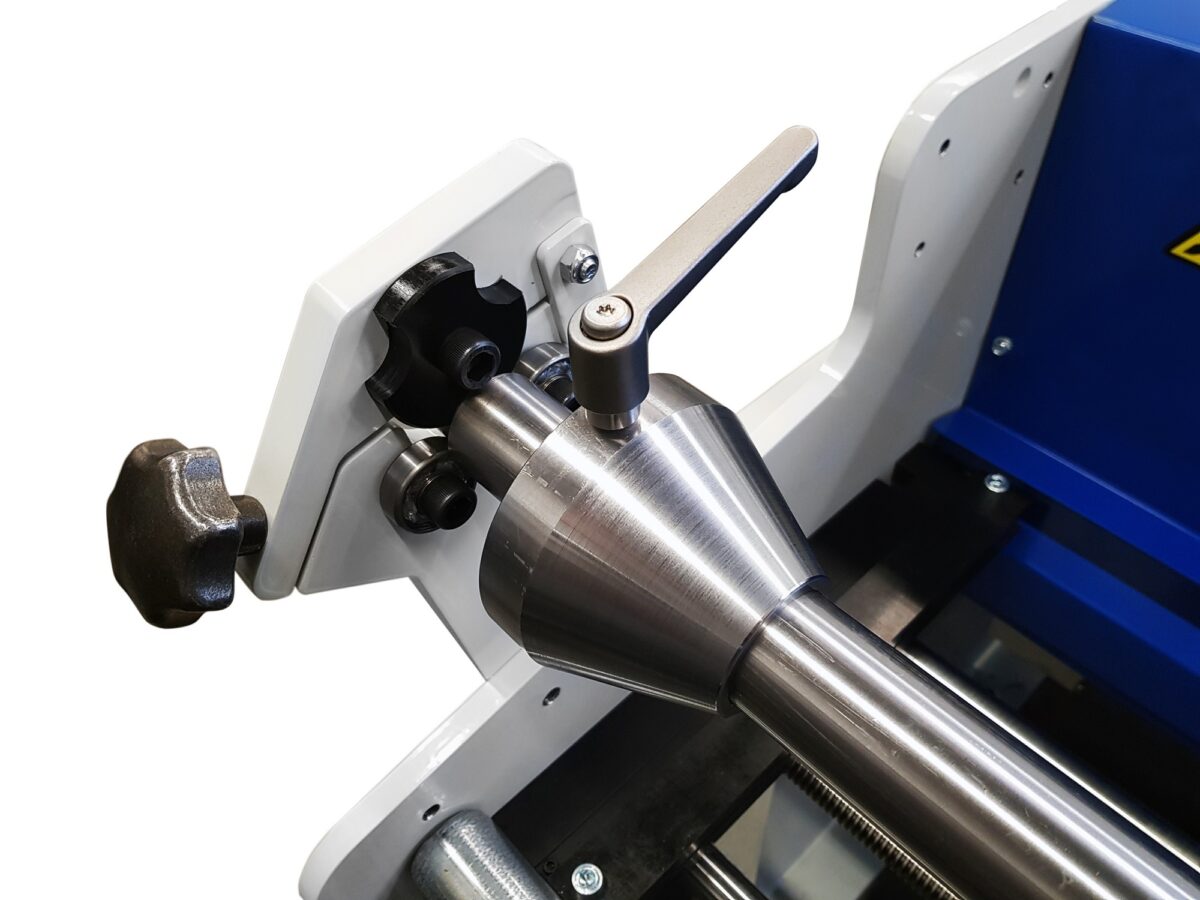

- Automatic adjustment of the straightening and feeding rolls, slitter shaft

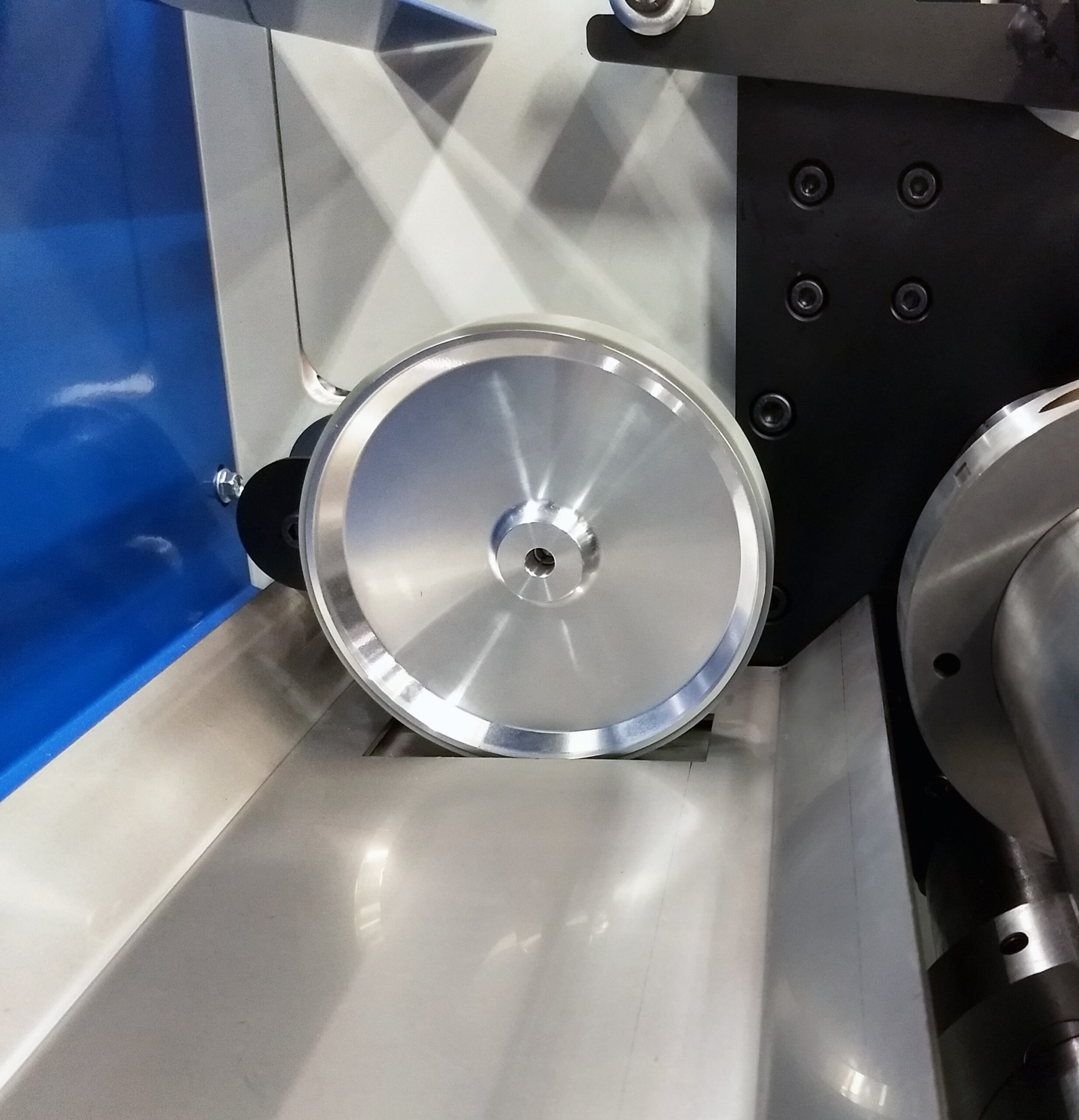

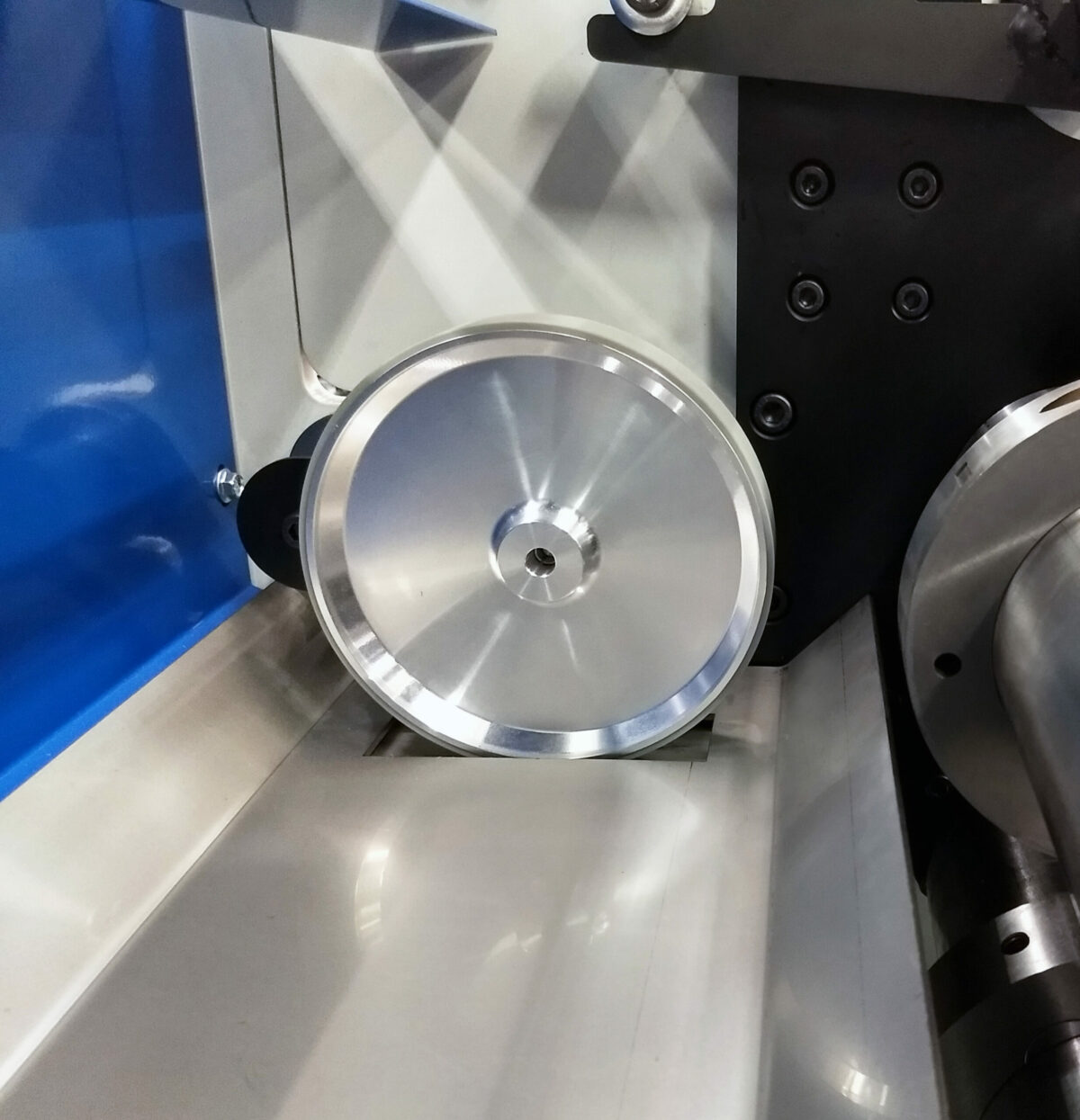

- Quick change two-piece slitter knife system- full repositioning of knives in less than 3 minutes

- Adjustable slitting knife depth based of material thickness to eliminate chamber of the work piece

- Gibb slitter knife engagement which eliminates side movement of the knives helps ensure long blade life

- Quick release with locks, fully adjustable coil guides prevent material side movement

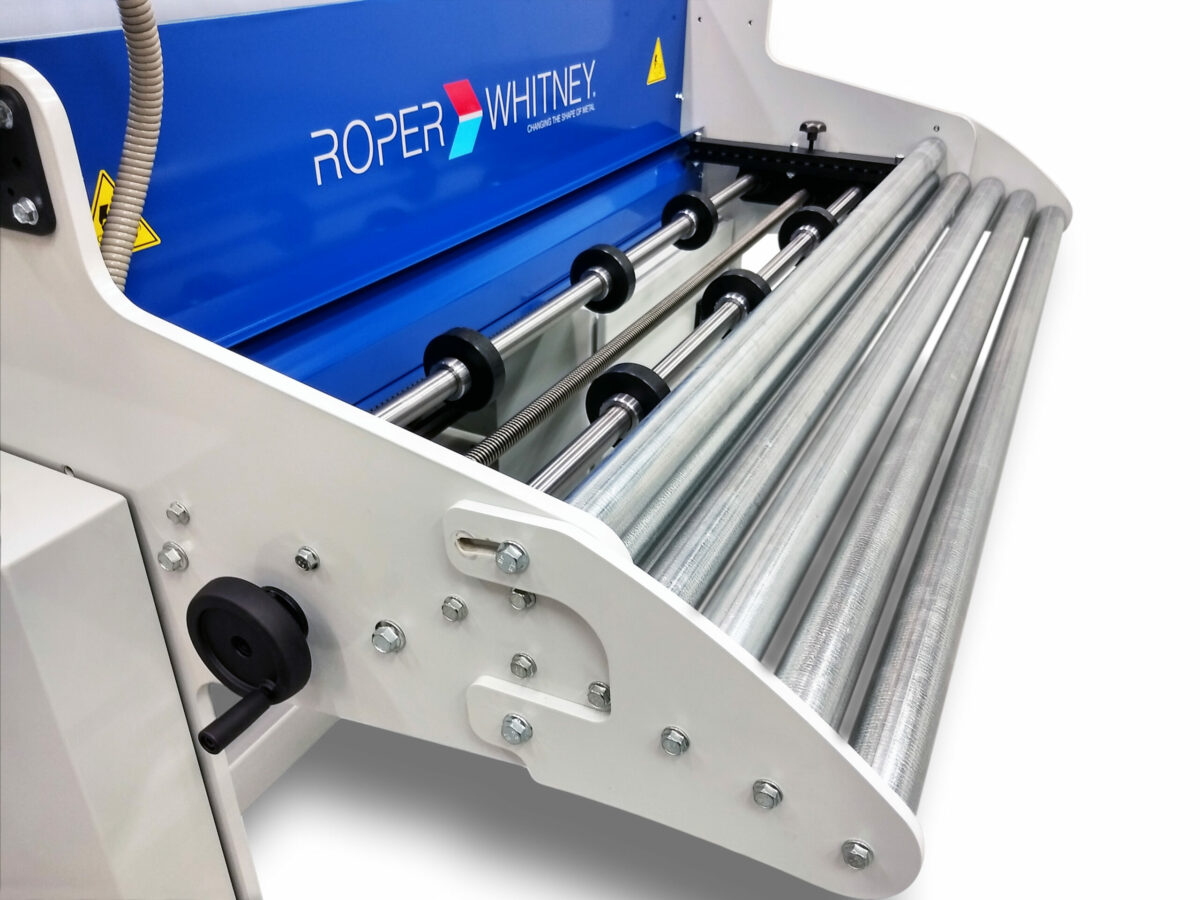

- Adjustable deflection rollers to better support the infeed of material from the coil

- Durable powder coated surface finish

- Sight-line visibility of feed materials

- Safety interlock system designed to CE Standards

- World renowned Schneider electrical components

- Easy to use Schneider operator interface with light tower prompts

- Material saving features including auto-clean cut alert at the jobs end to eliminate waste

- Variable speed drive enabling long lengths to be produced more quickly and more accurately

- Automatic material length calibration

- Variable speed acceleration for use with a wide variety of decoiler designs

- Adiprene coated feed rolls with cam adjustment for raising and lowering prevents marking of materials

- One over Two straightening rolls with automatic adjustment for accurate repeat setups

- Integrated electro-mechanical shear design for fast, quiet shear operation

- Two cutting edge top and bottom shear blades

- Decoiler options available