Shear may be added to most any punch (1/2″ or larger) to reduce the shock load on machine components and the punch and die, and increase their life expectancy. Shear, in essence, proportions the force through part of the stroke length of the ram – much less material is being cut at any one time than would be with a punch without shear.

THERE IS NO ADVANTAGE OF ADDING SHEAR TO SMALLER THAN 1/2″

Two types of shear are added to most Roper Whitney punches:

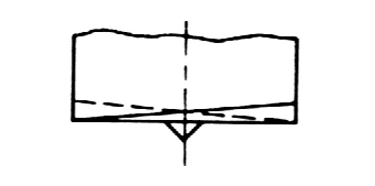

Crisscross Shear

Round punches 5/8″ diameter or larger, and square punches 11/16″ and larger have the crisscross shear.

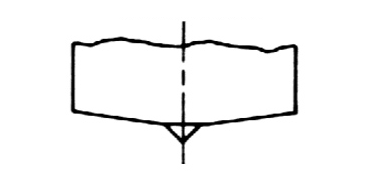

Housetop Shear

Rectangular and obround punches with 1″ major dimension and larger have the housetop shear.

Shear is most effective when punching 14 gauge or lighter materials. It can reduce the punching force by as much as 50 percent.

Example: Chart 1 shows that 11.3 tons are needed to punch a 4″ diameter hole thru 20 gauge mild steel. A punch with shear reduces the force to 5.7 tons.