Pioneering Automotive and Aerospace Solutions through Partnership with Eckold

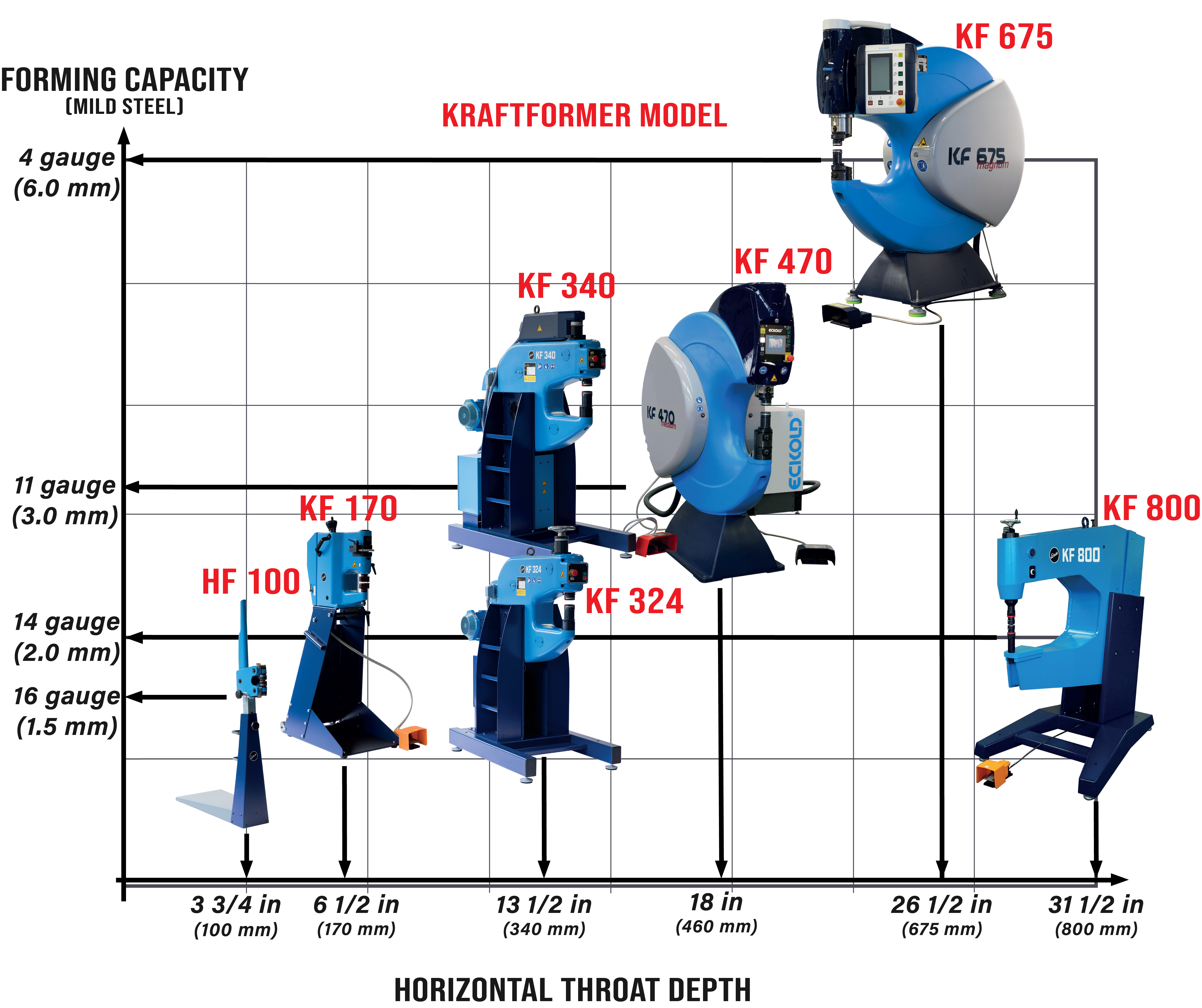

Eckold machinery, crafted in Switzerland, sets the standard in cold forming metal shaping with techniques like shrinking, stretching, and planishing. Renowned for precision, these machines embody the peak of durability, efficiency, and versatility in metal forming technology. Roper Whitney, the official U.S. distributor, ensures that industries across America have access to Eckold’s innovative equipment.

This partnership is pivotal in sectors such as automotive and aerospace, where advanced technology and precision engineering are critical. Together, Roper Whitney and Eckold deliver top-tier sheet metal fabrication solutions that meet the stringent demands of these industries. Their state-of-the-art machinery ensures that manufacturers can maintain a competitive edge by producing high-quality components that meet and exceed industry standards.

Roper Whitney and Eckold provide a wide array of machinery and technologies designed to cater to the automotive and aerospace sectors, including:

Clinching and Joining Systems

Eckold’s innovative solutions for sheet metal joining and assembly, ideal for the fabrication of lightweight and strong components in automotive and aerospace applications.

Shaping and stretching Technologies

Advanced machinery for forming and shaping sheet metal, providing the flexibility and precision required for producing automotive and aerospace components.

Eckold Machinery

All Eckold Products

Looking For Tooling?

815-962-3011 or email info@roperwhitney.com