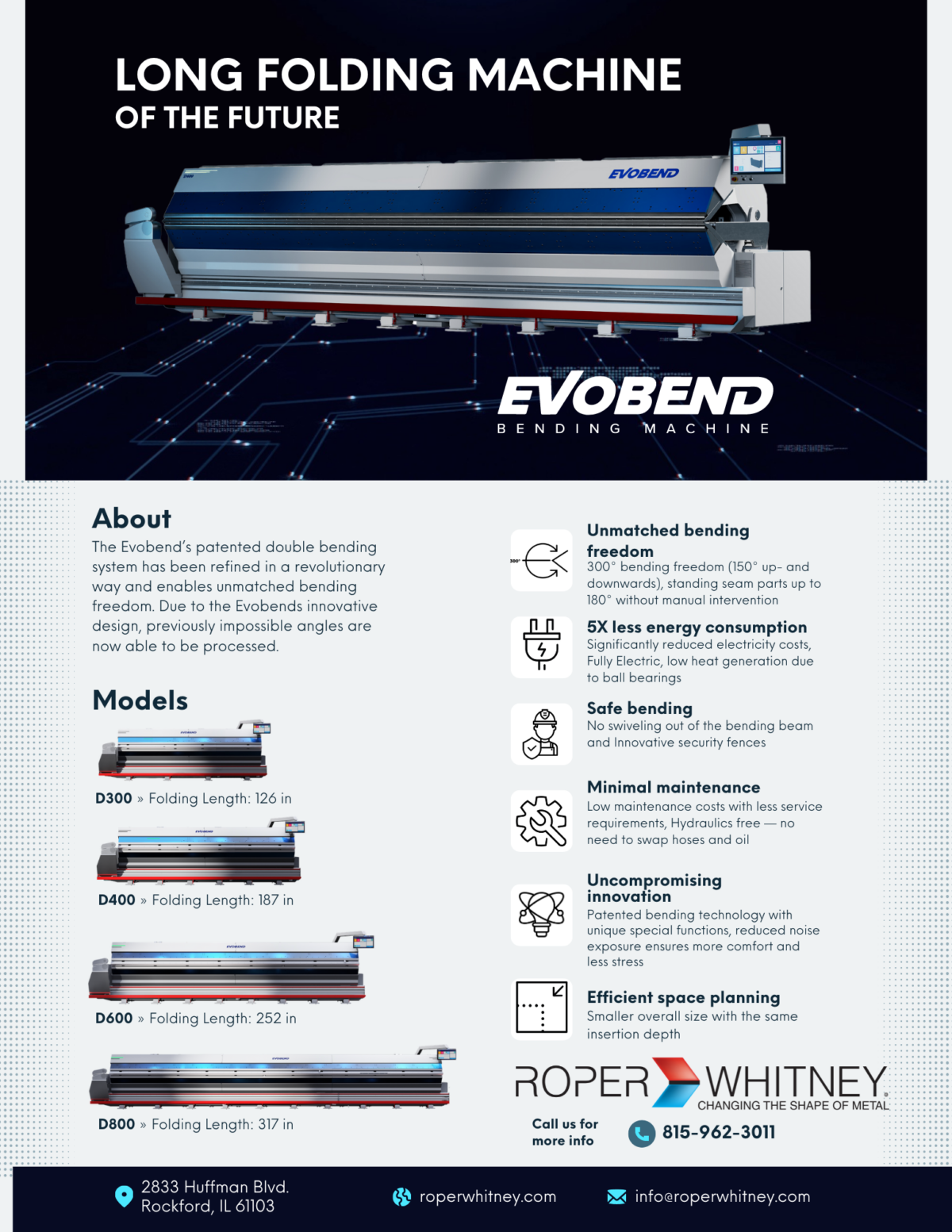

Roper Whitney is proud to showcase the Evobend, a revolutionary addition to our folding machine lineup, designed to handle a vast array of complex bending tasks with unmatched precision. The Evobend’s advanced tooling design, coupled with state-of-the-art control and servo motors, allows it to perform intricate bending operations automatically, significantly boosting workplace efficiency and safety.

The Evobend has no swinging bending beams. Instead, flush with the slanted work clamps are upper and lower bending tools that slide toward the workpiece. A hooked tip on each bending tool gives it the ability to make bends past 90 degrees. The bending tool on the lower clamp slides up to make positive bends, while the bending tool on the upper clamp slides down to make negative bends. The machine’s upper and lower clamping tools are slanted to provide 300 degrees of bending clearance. If the first flange is bent in one direction 150 degrees, the second flange can be bent in the other direction by up to 300 degrees.

Traditional folding machines often require operators to manually force materials into the machine, posing safety risks and physical strain. The Evobend eliminates this need by incorporating a servo drive system and unique tooling that “pinches” the material, manipulating it with small movements, and accurately. This reduces operator intervention and minimizes the risk of accidents, ensuring safer and more efficient operations. The Evobend boasts a unique bending principle allows for highly precise and complex bends. This flexibility is crucial for fabricators producing intricate profiles and custom parts.

Unlike press brakes that measure force in tonnage, the Evobend and other sheet metal folders from Roper Whitney are distinguished by their material capacity ratings. Specifically, the Evobend handles materials up to 14 gauge mild steel or 2.00 mm thickness. The integration of servo-driven technology facilitates precise control over the bending process, creating detailed and consistent profiles across various materials. This streamlines production and maintains high-quality standards without the physical toll of manual bending processes.

In today’s manufacturing environments, space is often at a premium. The Evobend’s compact design optimizes workshop layouts by minimizing its footprint. Movable safety fences can retracted when not in use, freeing up valuable floor space and allowing for easier maneuverability.

Unlike traditional long folding machines that rely on hydraulic components, the Evobend utilizes servo motors for all operations, eliminating the need for hydraulic maintenance and enhancing reliability and efficiency. The absence of hydraulic fluids and pumps reduces environmental impact and the risk of leaks and spills and also aids space saving.

The all-electric servo drive system of the Evobend is not only maintenance-free but also energy-efficient. By reducing power consumption, the machine helps fabricators lower operational costs and minimize their environmental footprint. The efficient use of energy also contributes to a quieter working environment, improving overall workplace conditions.

Safety is at the core of the Evobend’s design. Equipped with comprehensive safety features, including movable safety fences, light curtains, and laser systems, the Evobend creates a secure working environment by preventing accidental access to moving parts, and no swiveling folding beams. Additionally, it is fully covered, with no access to moving parts, and risk of debris getting within the machine.

In conclusion, the Evobend represents a significant leap forward in sheet metal fabrication technology. With its all-electric servo drive system, unique bending principle, and comprehensive safety features, the Evobend offers unparalleled precision, efficiency, and reliability. Designed with the operator in mind, it combines ease of use with advanced technology to meet the demands of modern manufacturing. Whether you’re looking to increase production, improve safety, or reduce maintenance costs, the Evobend is the ultimate solution for your sheet metal bending needs.